We're championing a new sustainable ultra-strong wood pole manufacturing technique that reduces material use by up to 85% and are calling on industry colleagues from across energy and construction to support the development of Pollywood Ltd, a British start-up, to help it deliver significant environmental benefits in new markets across the globe.

With Northern Powergrid’s support, Pollywood has developed a new super-strong construction material that has a better weight to strength ratio than steel, using a fraction of the raw materials. The innovation follows a project originally kick-started by international innovation broker the Energy Innovation Centre (EIC).

Now the companies are urging more businesses across multiple sectors to get involved to bring it to market and realise benefits across many UK sectors.

Steve Crighton, MD of Pollywood and the inventor of the technology, confirmed: “We’ve started to develop it for the electricity industry, however a materials innovation exercise showed nearly 200 potential uses across more than ten industrial sectors – making it a British-grown innovation that could change the face of construction and open up a new lease of life for the British wood industry with a new sustainable, valuable material.”

Northern Powergrid’s support and £106,000 investment via the EIC progressed this project from initial conception to prototype stage over the past 24 months. To date it has successfully proved its feasibility with a 1.5-metre prototype. A further £1.4m investment is now needed so Pollywood can develop new machinery capable of creating larger structures and progress to progress from the prototype stage, when it will become ready for market roll-out.

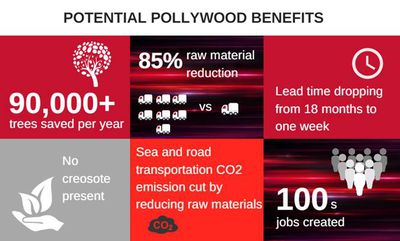

The innovation will also see manufacturing jobs returning to Teesside, as the inventors look to grow the business with British talent. Ten to 12 jobs will be created in the next phase with hundreds created when the business moves into full scale production.

Pollywood is made using a new manufacturing method, which enables the production of any length required of a lightweight, super strong hollow product capable of replacing previously solid structures. A staggering 60,000 new wooden electricity poles are needed in the UK every year, with a further 50,000 in the telecoms industry. The current poles can also take up to 18 months to source and deliver, because exactly the right kind of Pine tree has to be sourced. In addition, these trees must be treated with creosote, a carcinogenic substance being phased out across the EU. In addition, a move from DNOs storing poles on numerous sites to a ‘manufactured to order’ process would improve efficiency and release additional storage capacity.

In response to these challenges, Pollywood invented a new manufacturing method that can create between six to seven hollow Pollywood poles from one tree and requires no coating substances. The prototype tubular poles are made by sustainably combining the raw materials to make a long lasting, lightweight and cost-effective product made from wood fibre and natural bio-based resins. All the materials are natural and procured from renewable sources. Initial tests have established that the material will exceed the current industry standard for electricity poles.

Traditionally, one tree can only create one pole and so Pollywood has the potential to save more than 90,000 trees a year. The reduction of the raw material needed by up to 85% will also see a similar reduction in fuel needed to ship the materials from mainland Europe. Lead times for the poles will also reduce. Currently it can take 18 months to source and prepare a pole, however Pollywood will be able to manufacture ready-to-use poles in just seven days.

Traditionally, one tree can only create one pole and so Pollywood has the potential to save more than 90,000 trees a year. The reduction of the raw material needed by up to 85% will also see a similar reduction in fuel needed to ship the materials from mainland Europe. Lead times for the poles will also reduce. Currently it can take 18 months to source and prepare a pole, however Pollywood will be able to manufacture ready-to-use poles in just seven days.

Northern Powergrid plans to use Pollywood poles across its operations. The DNO delivers power to 3.9 million homes and businesses in North East England, Yorkshire and northern Lincolnshire through more than 17,500 miles of overhead power lines, which are supported with solid wooden poles.

Iain Miller, our Head of Innovation, commented: “We have a strong culture of innovation at Northern Powergrid. Our investment in Pollywood is a part of a £29m innovation project designed to discover and develop products and projects that can have a lasting positive impact on the environment, our business and our region – and improve the services we deliver for our customers. Pollywood has captured our attention because it covers these impact areas so well. As a business it’s a real challenge to keep enough stock of poles and we are forced to stockpile huge quantities just in case of a bad storm. Not only will Pollywood shorten sourcing times due to their manufacturing methods, but we’ll also get a stronger and more sustainable, durable product that should be able to withstand more arduous weather conditions – leading to less replacement need and improved reliability for our customers.”

As a completely new manufacturing technique, Pollywood has untapped potential. The Pollywood team plan to bring valuable employment to Teesside in the North East – an area that is in line for major redevelopment following economic decline. Pollywood Chairman, Quentin Kopp, added: “Around Teesside we have seen a decline in good quality employment opportunities. Pollywood has the potential to bring decent and proper employment back to the North East. This has been a key driver for the development of the new material.”

Iain added: “What appealed to us most about partnering with Pollywood is that not only will it help our day-to-day operations but it will also bring direct and positive benefit to the employment opportunities on our patch.”

Tony Knowles, Technical Manager at the EIC, said: "We are thrilled that we have been able to facilitate progress between Pollywood and Northern Powergrid on this ground-breaking project. The EIC is a broker, a partner, a scout and a gateway for innovation, with access to a range of commercial partners and a community of more than 2000 global innovators. Our linking of Northern Powergrid with Pollywood demonstrates our drive and determination to work alongside key players to bring the seed of an innovative idea to fruition. For ten years now we have been bridging the gap between large networks and small-scale SMEs, consistently providing an established route to market for innovative technologies."